A Case for Restructuring

Chris Joju • September 1, 2022

Chris Joju • September 1, 2022

The Department of Structures within Redback Racing, aims to maintain an unwavering focus upon streamlining elements of their design and manufacturing processes. As a result of prolonged introspection, Structures had recently made the decision to develop a more efficient internal hierarchy to assist with the efficient delegation of tasks. The Department has therefore made internal changes to realise their goals, recently undergoing a major restructure complete with an overhaul of pre-existing sub-departments in order to maintain a clearer understanding of timelines and projects throughout the Design Cycle.

Before the accommodation of changes to sub-department responsibilities, Structures was comprised of two sub-departments:

Pre-Restructure, it was observed that there remained an imbalance in the workload associated with Frames and Ancillaries, with Ancillaries in particular being responsible for most of the structural components of RB21-E. Furthermore, issues relating to the manufacturing process, specifically in regards to project management and the sub-optimal utilisation of resources, had hindered efficiency and prompted a need for the re-evaluation of priorities. The identification of these key barriers has led to a purposeful decrease in the responsibilities held by any one sub-department.

Structures is now comprised of the following four sub-departments:

With each having roles and responsibilities wholly distinct from each other, previously unsegregated tasks of dissimilar nature are now grouped together, allowing for Managers to accurately keep track of projects and provide more accurate project timelines. The involved nature of the work Structures carries out means there is a need for frequent meetings so as to look over physical components alongside calculating frequent cost-benefit analysis of potential choices. Pre-Restructure, the presence of 2 sub-departments of a larger body of members often lead to a disruption of workflow brought about by unavoidable schedule conflicts. Post-Restructure however, smaller sub-departments lend themselves to scheduling meetings more easily, allowing for a smoother progression of tasks. Meetings are essential as the process of working with tangible parts require in person inspections in order to aid with the visualisation of components, particularly with newer members slowly becoming accustomed to set practices.

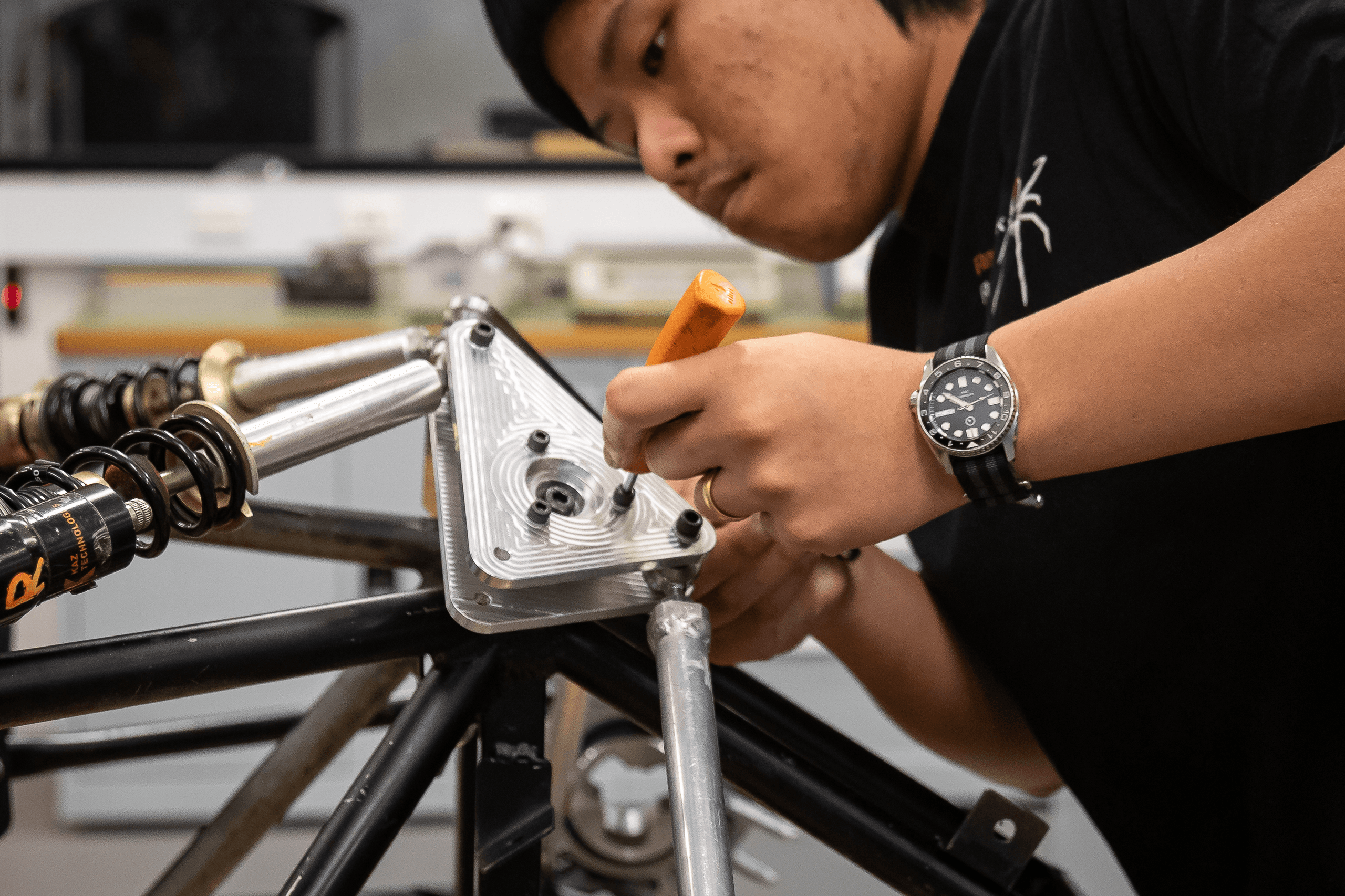

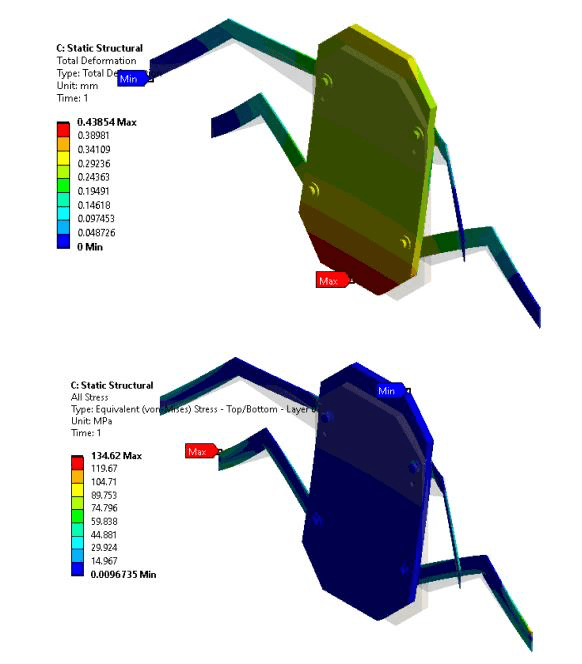

A principle of 'measure twice, cut once' is also now in place, enabling for the minimisation of wastage alongside decreasing labour hours associated with prototyping parts multiple times. Operating under this framework of relying upon the experience of senior leadership, Structures is now able to more readily identify mistakes at earlier stages, avoiding a repeat of previous mis-steps. As a result, there has also been a greater focus upon the formalisation of verification processes, as previous methods of task delegation operated under an informal manner. Post-Restructure, this formalised approach involves a period of research into the limitations imposed by FSAE-A (Formula Society of Automotive Engineers Australasia) rules to ensure compliance. Thereafter, a Computer Aided Design of the respective component is created, with this design being checked over and confirmed by Managers. After confirmation, a FEA (Finite Element Analysis) simulation of expected real-life conditions is carried out with the required inputs for rule-compliance being dialled in. Upon validation, a manufacturing plan is generated and once given the go ahead by Managers, manufacturing begins.

Image of headrest mounts from Rich + FEA Analysis

A core issue Pre-Restructure was that of focus on projects being stretched thin, possibly leading to a compromise on driver safety. Redback Racing maintains a strong 'safety first' mindset, with increased performance at the expense of Driver Safety being negatively viewed upon. It is only after satisfactorily meeting baseline requirements that efforts are made to innovate in order to improve cost, manufacturability, and potential weight reductions to improve performance. Post-Restructure, the Department has specifically introduced a sub-department titled 'Driver Safety' in order to ensure Drivers remain safe in all stages of testing and competition. This act of honing in on specific issues and addressing them to a more than satisfactory extent was not feasible Pre-Restructure and had remained an unresolvable issue.

The Restructure has been a net-positive for Driver Safety owing to improvements associated with task delegation and responsibilities. Even as transitioning from old sub-departments remained slightly difficult owing to incomplete tasks, Driver Safety is able to more effectively utilise increased manpower from new members, focus on niche areas of Driver Safety previously only explored in a shallow manner, and allow for students with a specific interest in designing safety components ample opportunity to improve their skill-sets and pursue their passions.

Specifically for Chassis, the Restructure has been largely positive in nature albeit with some drawbacks. Pre-Restructure, completion of projects involved designing the component itself and any necessary mounts/jigs coupled with the eventual manufacturing of the component. But due to Chassis' strong intra-department links, the latter stages of the process of designing components may be handed off to another associated sub-department. This was the case with the manufacturing of the Headrest Mounts, as the sub-department of Mounts received a design for the component from a Chassis member and completed manufacturing. Even so, the decrease in ambiguity alongside a more balanced workload outweighs some of the minor drawbacks of the Restructure with members able to also maintain greater focus upon specific components of the Car. New members have remained willing to learn and enthusiastic, having been provided the necessary support and guidance from more experienced students.

Through a combination of onboarding new members, revitalising tasking processes, and subsequent clarification of internal responsibilities, Structures has sufficiently addressed the key criteria put forth Pre-Restructure. Although the greater picture of these changes are yet to be fully realised, members have communicated greater clarity surrounding project expectations in the past few months. Redback Racing is eagerly looking forward to the positive impact of the implemented improvements as well as the flow-on effect of streamlining manufacturing processes to other Departments reliant upon Structures.